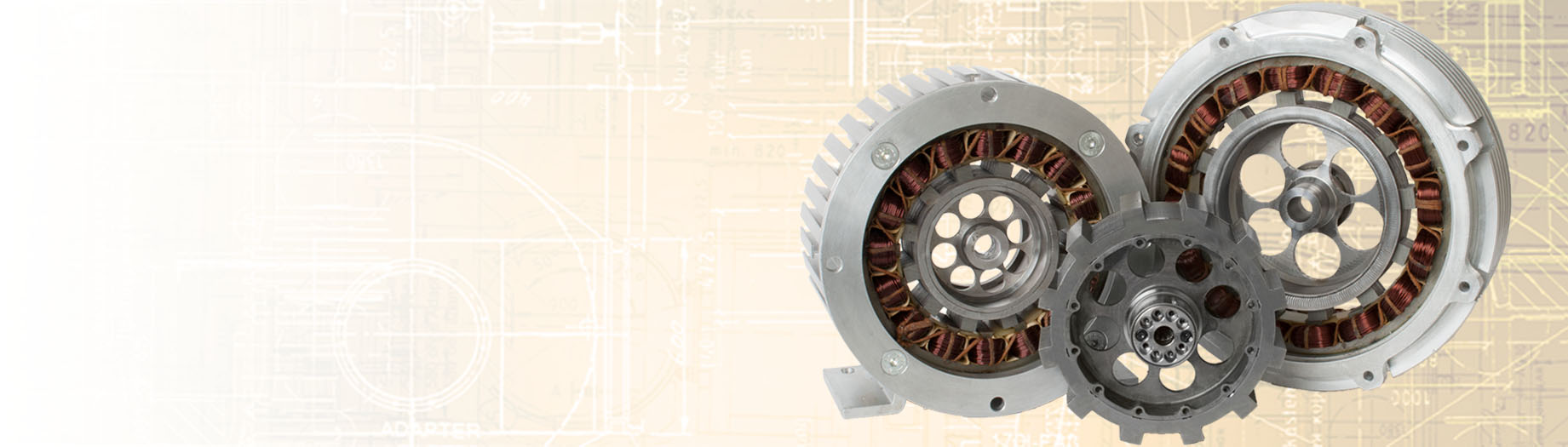

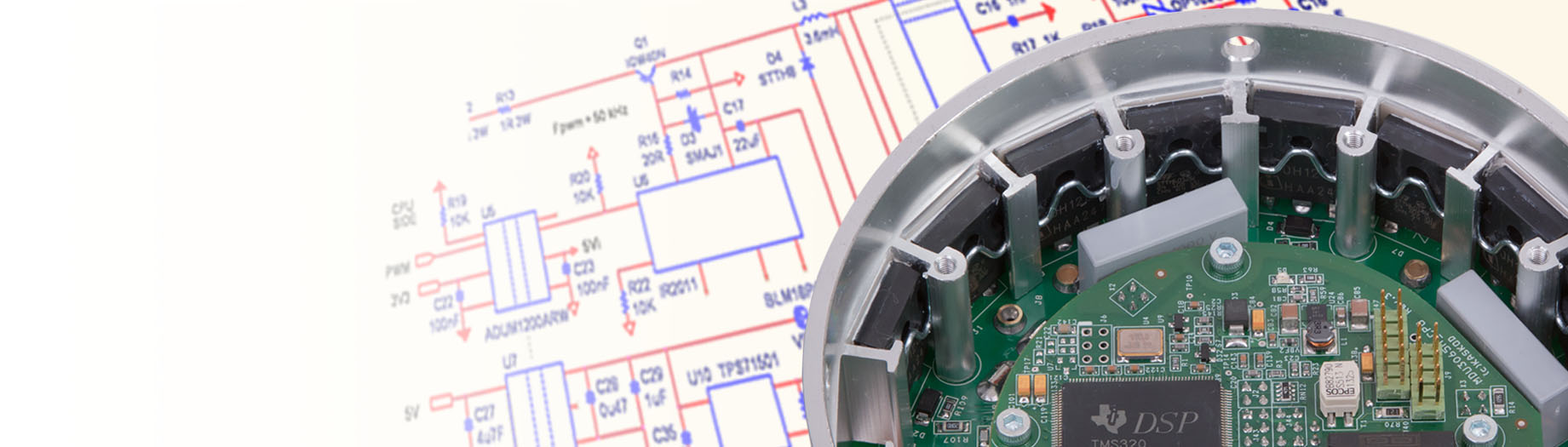

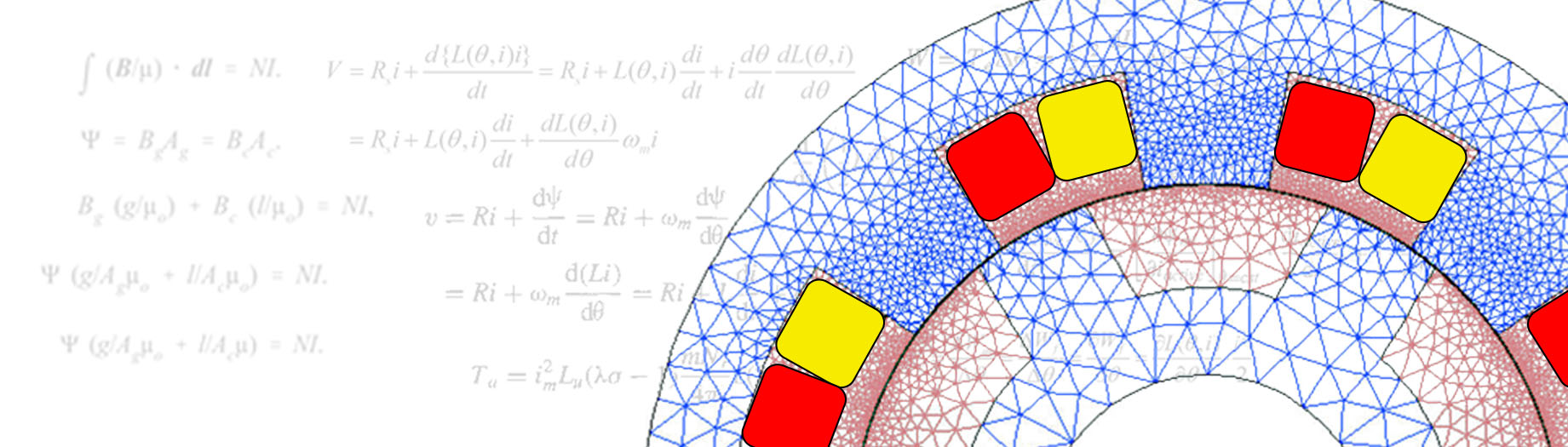

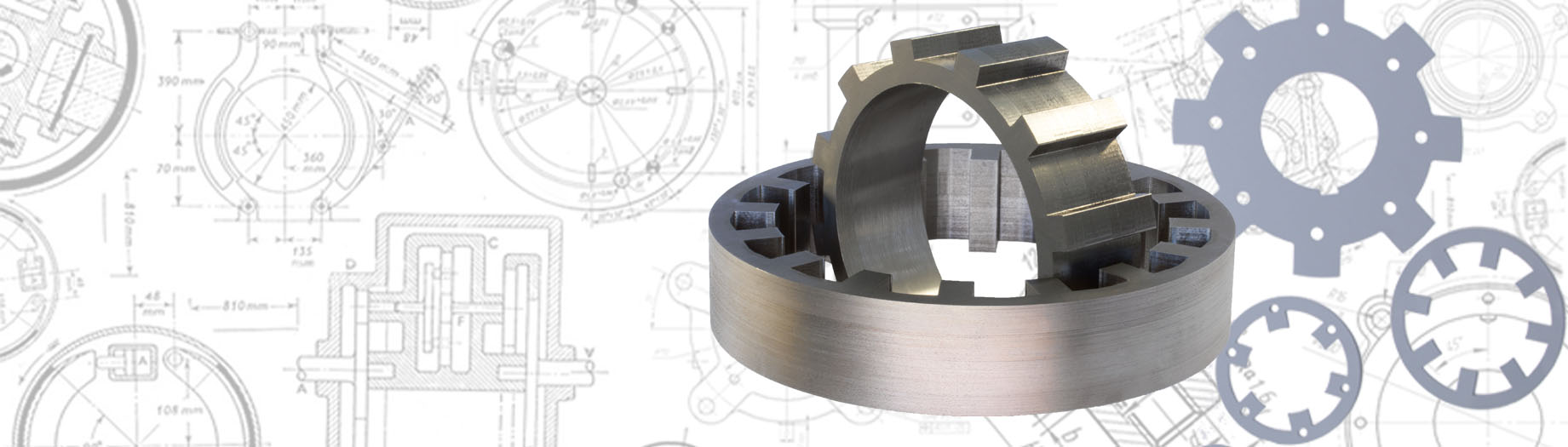

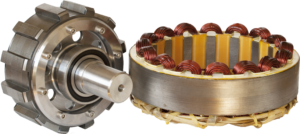

In contrast to well-known conventional generators Switched Reluctance Generator (SRG) have “toothed” stator and rotor, and have neither windings nor permanent magnets in the rotor. For their operation the excitation unit which is controlled in accordance with the rotor angle position is necessary. During the operation, active stator poles (i.e., those with winding coils through which the current flows) repel the nearest rotor poles. When the poles are repelled enough, the phase current via diodes is charging DC link capacitor. The excitation current is changed to the next phase by means of the power electronic switches depending of voltage of the DC link capacitor. This way the machine generates the power and keeps DC voltage stable.

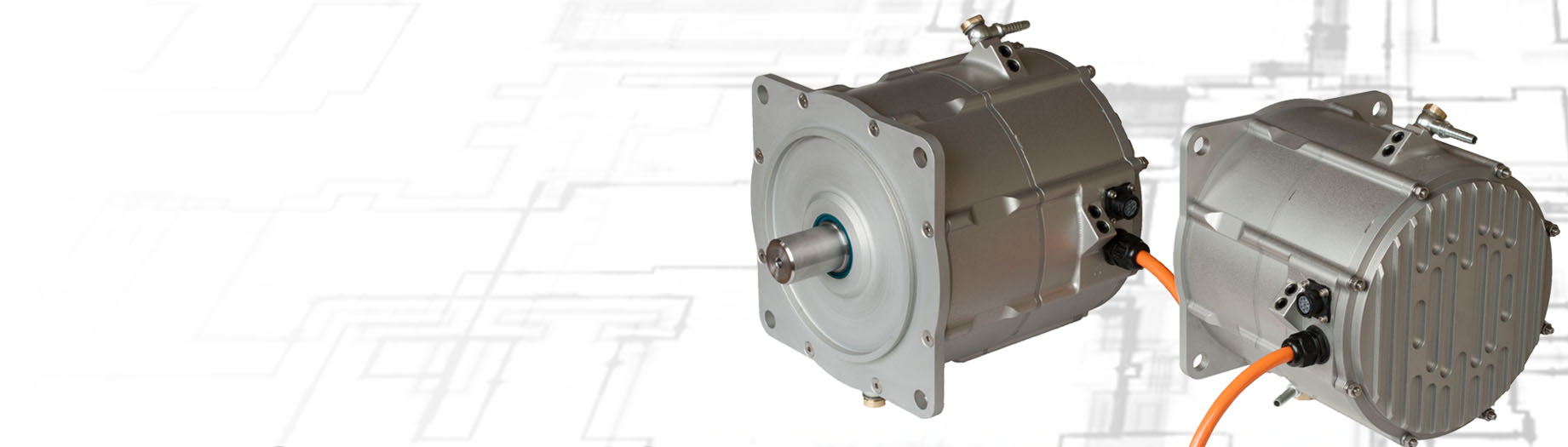

The unique operation results in unique advantages of the SRG. Absence of magnets and a passive rotor simplify construction and lower the cost of manufacturing. Rotor does not dissipate heat to speak of and in fact can be used to cool the stator, also making the machine less sensitive to high temperatures. Ease of cooling in turn simplifies the task of making construction hermetic.

Magnets in conventional electric machines lose their strength when heated or with time or they can be demagnetized by too high currents or high temperatures, can be contaminated with ferromagnetic dust, but SRG has no such problem. The excitation circuit of the SRG has full control over the output voltage which allows under fault conditions to de-energize the system within milliseconds while a machine with permanent magnets would still have output voltage present until the rotor stops.

Passive rotor reduces overall losses in copper winding because it does not have any. The power/weight and torque/weight ratios are higher than conventional synchronous machines. Since phases of an SRG are independent, the machine is very tolerant to open-coil fault (in the windings) and faults in the power converter.

The above features make SRG the most cost effective, the most fault tolerant and the most reliable electric machine in existence. But wait, it gets better! Due to sophisticated electronic sensorless control algorithms, the machine works perfectly like motor or generator. This feature allows to use this electric machine as a starter-generator in many applications.

The layout of SRG can be so flexible that not only the machine can be designed flat as a disk or oblong as a tube, but the rotor can even be placed outside the stator. This flexibility combined with simplified overall construction opens up an entirely new field of mechatronics that combines mechanics and electronics with information technology and computer control.

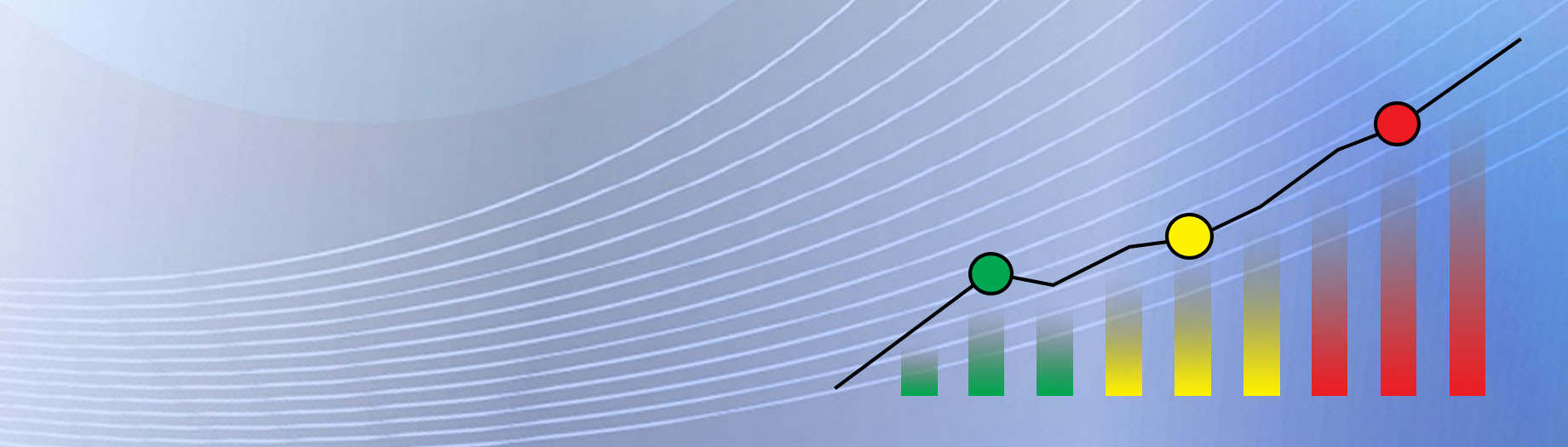

Switched Reluctance Generators are very reliable and efficient in high or low-speed applications.

In low-speed applications such as wind power systems, water turbines, the absence of magnets not only reduces the cost but also eliminates the cogging torque.

In high-speed applications such as steam and gas turbines, turboexpanders, micro-CHP systems etc., switched reluctance generators make it possible to get rid of gearboxes in electric power systems.

How high is the efficiency? With high quality silicon steels or alloys are used for rotor and stator, it could be 98% or even more, depending on speed and power (efficiency is higher in high-power applications and in DC mode vs AC).

Switched Reluctance Generator features:

- High efficiency over a wide speed range;

- Controlled excitation

- The most fault tolerant generator known;

- 4-quadrant operation, the machine can run forward or backward as either a motor or generator;

- A simple rotor without magnets or windings;

- Low inertia;

- No cogging torgue problem;

- Only stator requires cooling, due to low rotor heat dissipation;

- The lowest manufacturing cost of any generator;

- High power-weight ratio;

- Optimum generator for wide speed range;

- Optimum generator for high temperature environments;

- High repairability;

- Flexible layout construction: generator can be long or short (pancake construction), rotor can be inside or outside stator;

- Simple hermetic construction due to the fact that only stator requires cooling.