Ordinary gensets utilize diesel or gasoline combustion engines that are controlled to run at a fixed speed so that the directly coupled alternator driven by the engine produces voltage with a fixed frequency of either 50 or 60 Hz.

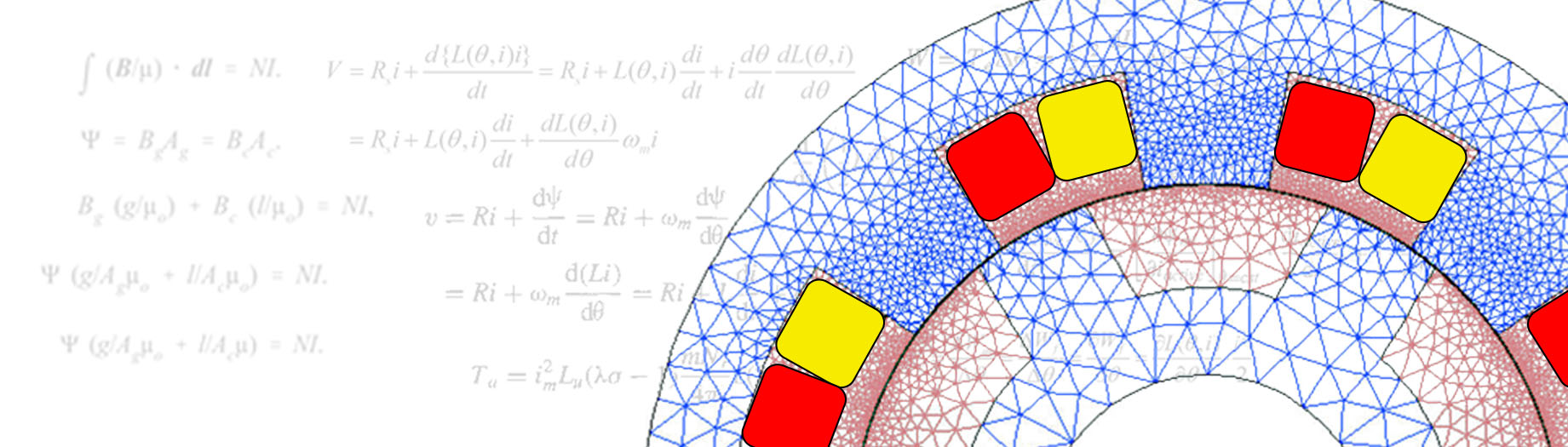

Switched Reluctance Generators (SRG) running the engine at variable speed and using power electronics to convert a variable rotation frequency of the prime mover to a fixed voltage and frequency allows for a more efficient operation of the genset. With advanced gasoline or diesel engines and variable speed technology it is possible to reduce weight by 30-60% or even more thanks to liquid cooling and increase fuel efficiency by up to 30-40% by adjusting the speed of the engine depending of the load. The speed of the engine is controlled via a user interface which allows the engine to run at it most efficient operating point for a given load and ambient thermal conditions. It is also possible to have the engine run where it is most audibly quiet, or at its least-polluting operating point. DC power capacitors of the SR generator make the genset less sensitive to load transients and increase the output voltage stability.

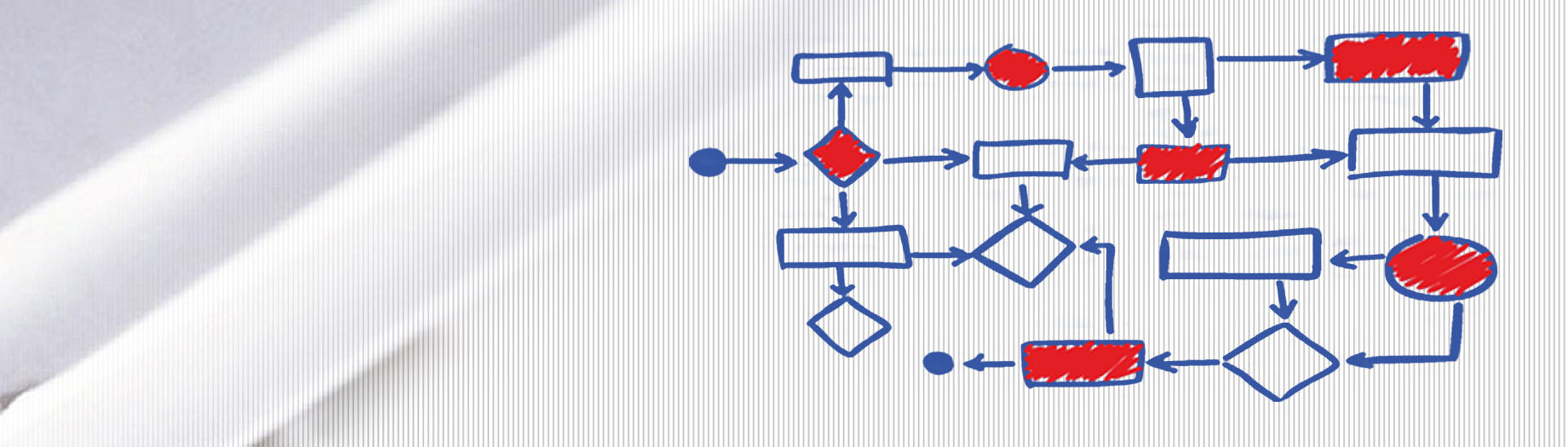

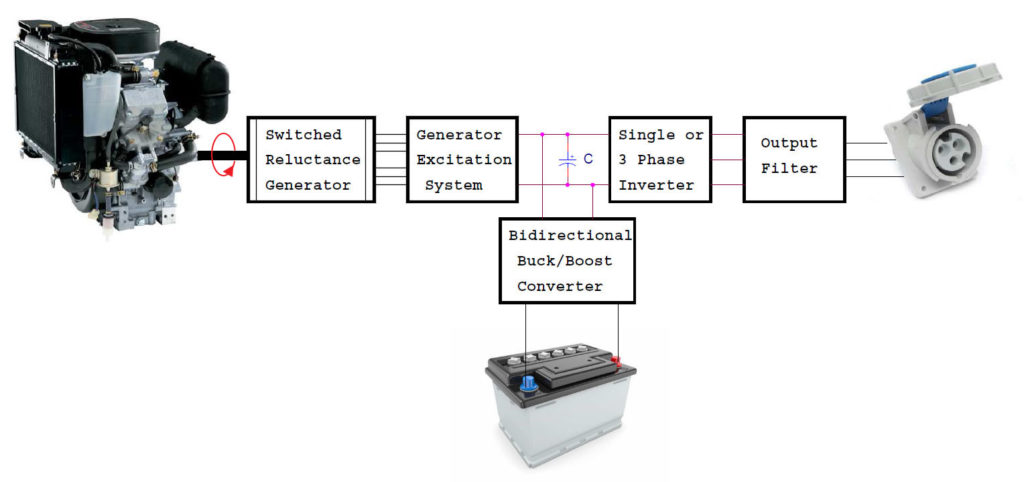

Functional block diagram of power conversion components in switched reluctance generator set

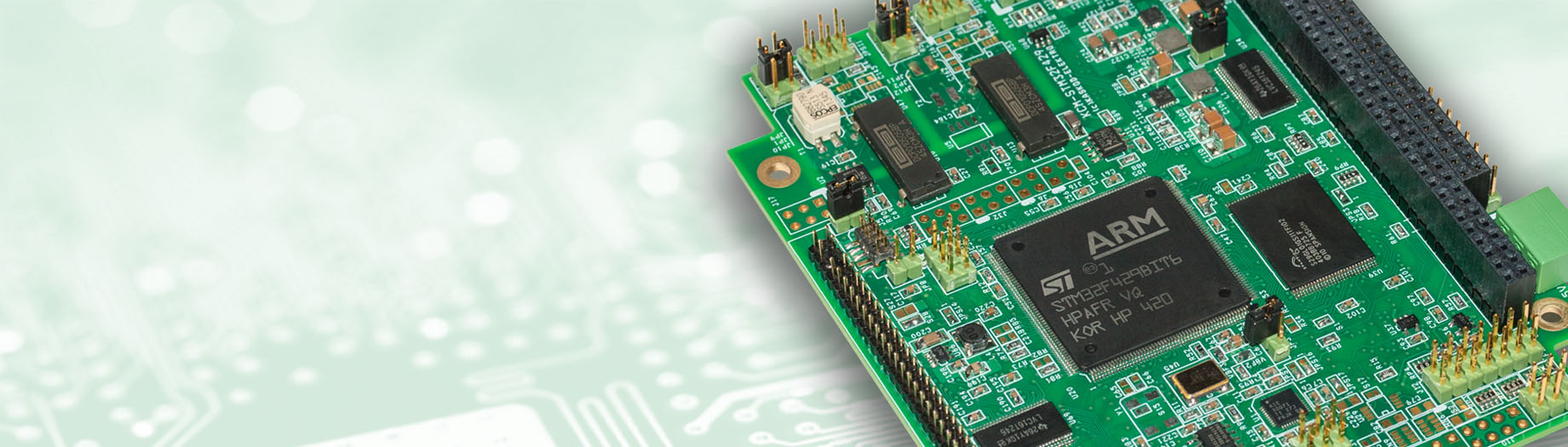

A block diagram of the electronic power conversion system for a genset featuring a switched reluctance starter-generator is shown above. The variable frequency pulses produced by the switched reluctance generator via diodes of excitation system charge capacitor C which stabilizes the output DC voltage and an inverter is used to produce controllable AC voltage with selectable frequency. Bidirectional back/boost converter charges the battery in operating mode and converts the battery voltage during the starting mode.

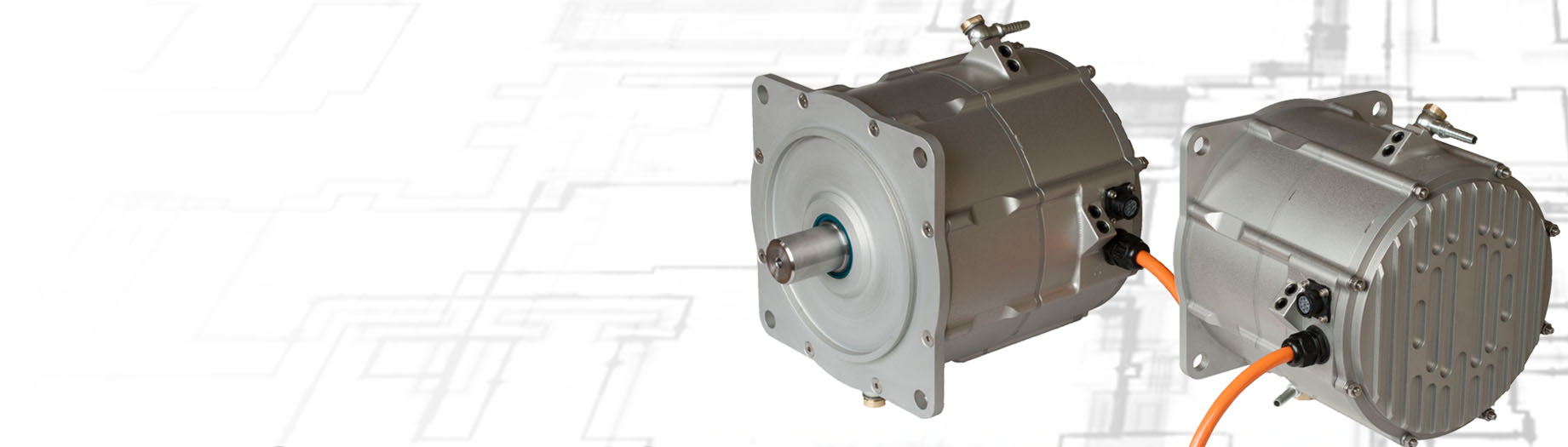

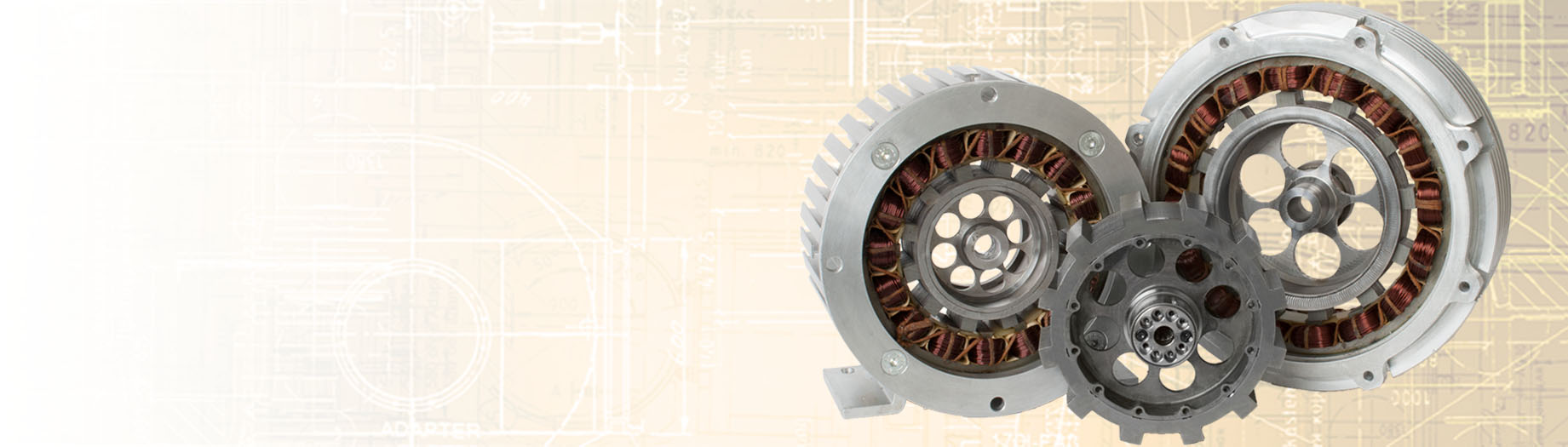

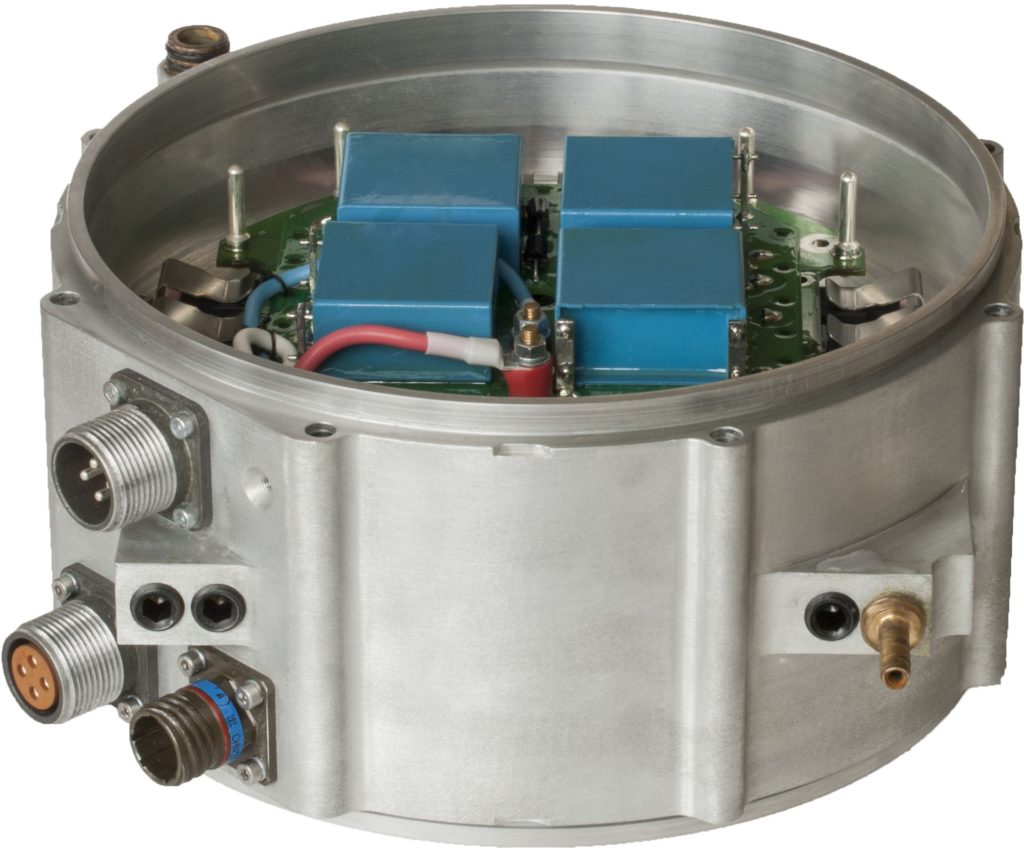

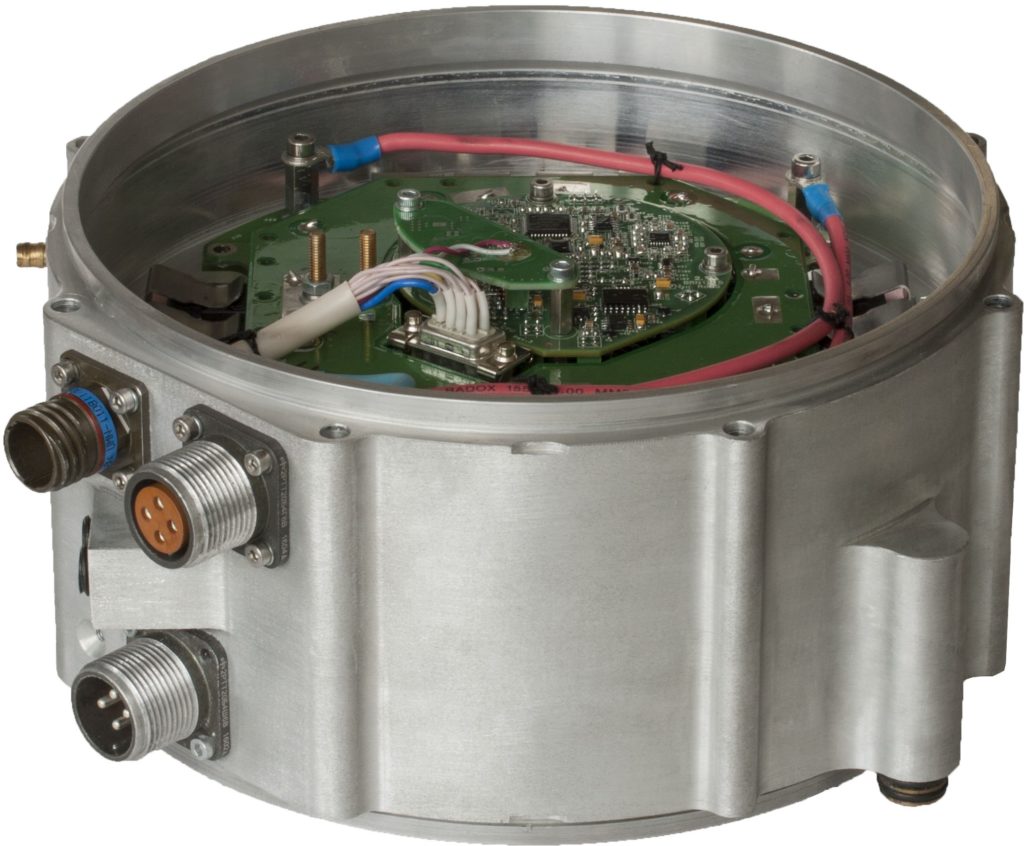

Liquid Cooled Switched Reluctance Generators with integrated sensorless excitation system and inverter.

Cooling: Liquid, water glycol

RPM range: 1000 – 4500

Sensorless control: New advanced algorithms

Nominal power: 2kW or 5kW or 10kW

Output Voltage: 208Vrms (L-L)/3-phase continuous at 60 or 400Hz or 380Vrms or 400Vrms (L-L)/ 3-phase continuous at 50 or 60Hz

Output Wave Form: Sinusoidal

Total Harmonic Distortion: Less than 3% at full load

Line/Load Regulation: Maximum В± 4% from no load to full load

Output Noise: (20MHz BW): High frequency ripple is less than 500mVrms

Output Overload Protection: Current limiting with short circuit protection. Thermal shutdown with automatic recovery in case of insufficient cooling

System Efficiency: Typically 92% at full load

Operating Temperature Range: -40В°C to +60В°C

Temperature Drift: 0.05% per В°C over operating temperature range

Generator protection class: IP66

Humidity: 5 – 100%

Weight: 11,6 kg (2kW), 19 kg (5kW), 25 kg (10kW)

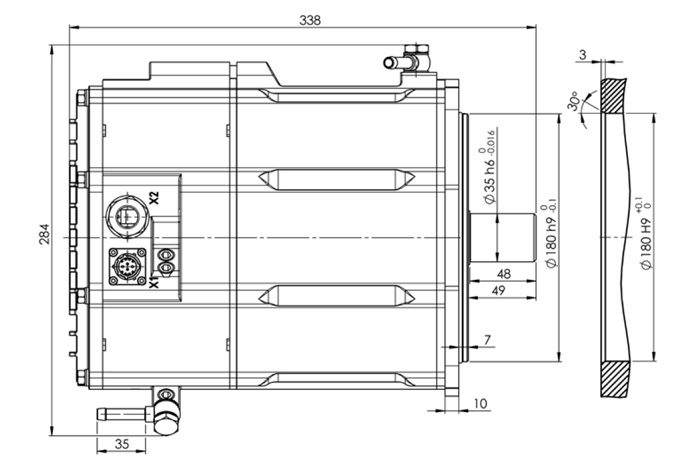

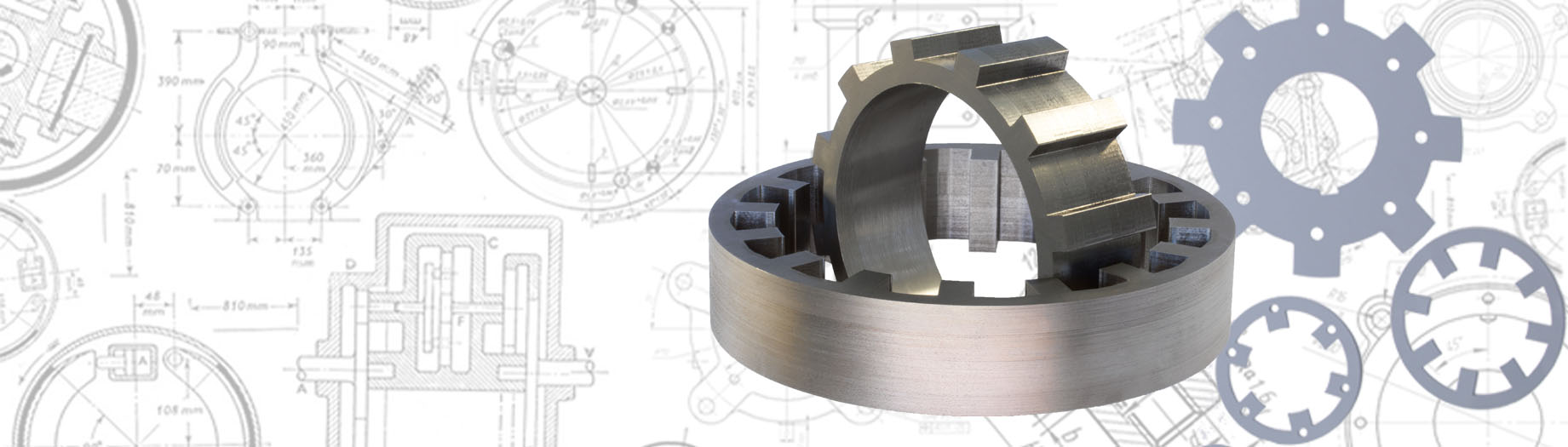

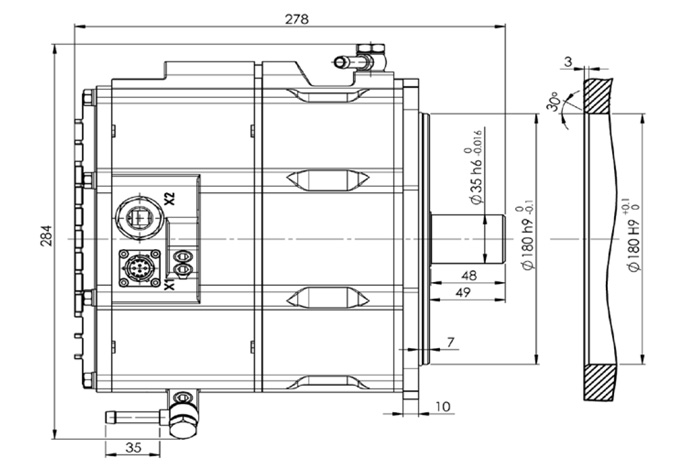

5kw generator dimension drawings